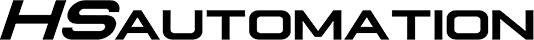

Palletizing Robot Systems

PALLETIZING ROBOT SYSTEMS

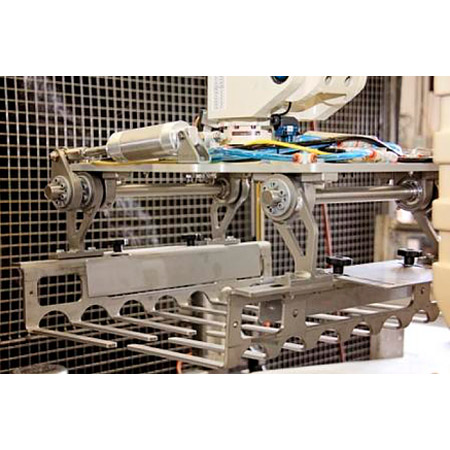

We specialize in robotic palletizing for stacking bags and boxes. We integrate Fuji Robots; their control system is the best in the industry for palletizing boxes, bags and other products. We are Canada’s largest Fuji integrator and have sold systems all throughout Canada and the USA. Our robotic systems can have your products packaged, palletized, shrink-wrapped, and ready for shipment. We offer a selection of bag automation, which allows us to provide a turnkey solution-from the bottom of your bin, to the wrapper pallet, ready for the warehouse.

Contact Us

Phone

519-245-2310