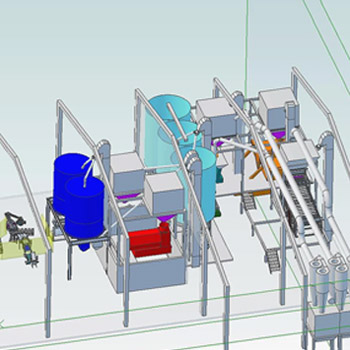

Bag Filling and Closing

Grain and Seed Processing Equipment

Robotic Integration

HS Automation is a family run company, with over a 100 combined years experience in seed and grain processing. We specialize in bag filling/closing, and robotic palletizing. Using world class equipment, we will custom build a system to suit your production needs.

From full automation to a simple setup, our team has the plant layout and automation expertise you can count on. We look forward to working with you.

Sincerely, The Hartwick Family

HS Automation Stacking 25 KG bags of Flour

Contact Us

Phone

519-245-2310